Bactiless : Reducing the Risk of Bacterial Contamination

Publiée le 02/11/2017 12:07Bacterial spoilage remains a common problem in wine, especially with risks associated with climate change (higher pH) and a perfectly reasonable desire to reduce sulphite levels in wine. Standard control methods are often insufficient to eliminate risks without having disadvantages in return. Bactiless™ is a new solution offering many advantages.

The various interventions on unwanted bacteria

There are currently various situations when you may want to take action to prevent bacterial populations developping.

- To avoid spontaneous malolactic fermentation (MLF) during alcoholic fermentation (AF), which often causes lactic disease in red wine (especially at high pH), or the production of unwanted buttery aromas in white and rosé wines.

- To deal with increased volatile acidity in wine during stuck alcoholic fermentation : increased volatile acidity can be due to various causes, such as stressed yeast, lactic disease and acetic bacteria development.

- Between AF and MLF in red wine : delaying MLF for microoxygenation.

- After MLF in red wine, to avoid acetic or giogenic amine deviations during ageing and storage. Wine may be vulnerable to lactic or acetic bacteria, either because you want to use less sulphites or because readjustment to SO2 levels cannot be done regularly enough.

- After AF in white or rosé wines, to prevent malolactic fermentation : unwanted loss of acidity, possible reduction of aromatic freshness, depending on which bacterial flora is active.

Standard Control Methods - Not Always Satisfactory

- SO2 is probably the most widely used method, although it has disadvantages : low bactericidal power at high pH, consumers' desire to reduce SO2 levels due to its toxicity, readjustment required during ageing. SO2 may also cause negative sulphur odours if used during ageing on lees or alcoholic fermentation. In addition, SO2 is incompatible with microoxygenation.

- Lysozyme is an egg enzyme that can be used to control lactic bacteria only. Given its origin, this enzyme may have to be mentionned on the wine label. Since lysozyme is a protein, it may also contribute to protein instability in white and rosé wines.

- Physical methods, such as fining/racking/filtration, help reduce the microbial load but cannot be used at every stage of winemaking and are often inadequate.

- A preventive method is best when spontaneous MLF occurs too early and/or is unwanted on account of its uncontrolled effects on wine's sensory qualities. In some cases, L. plantarum ML Prime™ can be used pre-emptively. This product works very quickly, enabling MLF to be carried out during AF without any risk of lactic disease or buttery hints, even when residual sugar is present. When MLF is unavoidable, this product helps avoid collateral damage.

Bactiless™: a new agent to control bacterial populations

Bactiless™ is a 100% non-GMO, non-allergenic biopolymer of fungal origin (Aspergillus niger) that helps control bacterial populations ine wine. Bactiless™ has been formulated to reduce viable populations of acetic and lactiv bacteria. Although using SO2 strengthens its antibacterial effect, Bactiless™ can also help reduce the amount of SO2 needed to control bacterial populations.

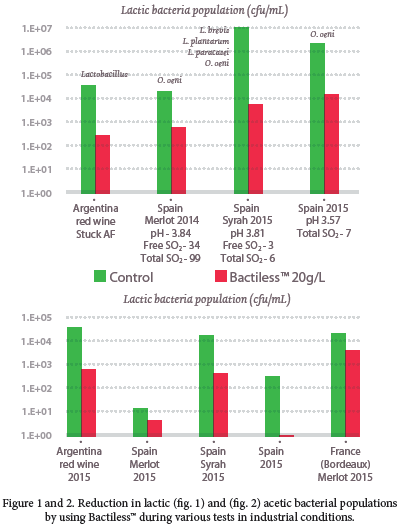

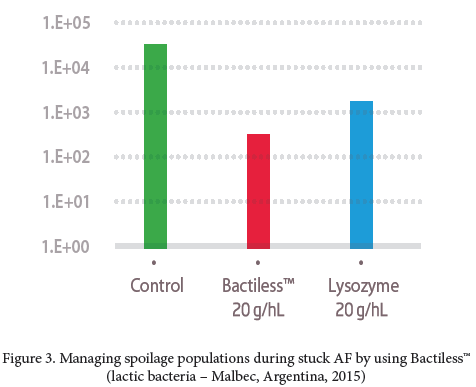

Bactiless™ is used to stop lactic and acetic bacteria growing after malolactic fermentation (figures 1 and 2). It is therefore a good alternative to lysozyme and large amounts of SO2. In trajectories without added sulphites, Bactiless™ helped achieve low volatile acidity. For stuck alcoholic fermentation with MLF in pomace, Bactiless™ also protected wine against microbial spoilage (figure 3).

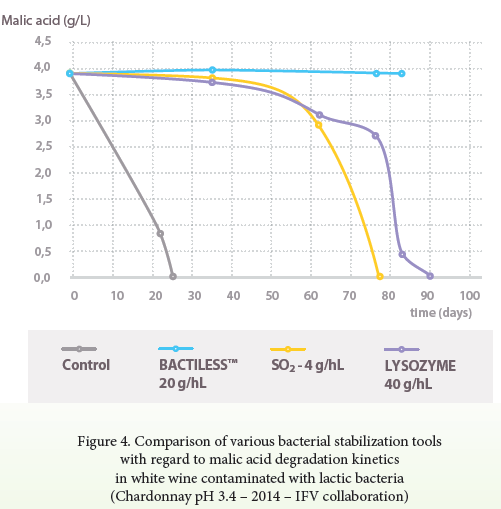

Bactiless™ is also used to delay or inhibit unwanted malolactic fermentation in white and rosé wines (figure 4). Bactiless™ should not, however, be used before MLF when you want to carry this out later since it can have long-lasting action.

Lallemand France/Switzerland/China

Lallemand SAS

fb.france@lallemand.com

Tel: +33.5.62.74.55.55

Lallemand Italia

fb.italia@lallemand.com

Tel: +39 (0) 45 51 25 55

Lallemand Península Ibérica

fb.espana@lallemand.com

Tel: (+34) 91 4415053

Lallemand Germany, Austria, Greece, Hungary, Israel, Cyprus, Malta, Poland

fb.eurocenter@lallemand.com

kburger@lallemand.com

Tel/Fax: (+43) 27 35 80 147

Ferment Croatia, Slovenia, Macedonia, Romania, Russia, Serbia, Moldavia, Ukraine

nmaslek@lallemand.com

Tel: (+385) 98 30 24 62

Lallemand North America, Mexico, Japan, Taiwan

gspecht@lallemand.com

Lallferm S.A. Chile, Argentina, Uruguay, Brazil, Ecuador, Colombia

pcarriles@lallemand.com

Tel: +54 (261) 425 67 89

Lallemand Australia , New Zealand

australiaoffice@lallemand.com

Tel: 61 (8) 276 1200

Lallemand South Africa

ploubser@lallemand.com

Tel: +27 21 913 7555