Wine bacteria to control Volatile Phenols and Brettanomyces

Publiée le 16/03/2018 15:01From the vineyard to the bottle, every step of winemaking impacts the quality in the wine. Climate change also affects the quality of grapes, especially the sugar levels and pH, and, consequently, winemaking conditions must adapt. The increase in sugar levels and pH also influence the micro-organisms present on the grapes and, of course, the yeast and bacteria populations.

The interactions between these micro-organisms are very complex and winemakers must manage alcoholic and malolactic fermentation taking into account the evolution of grape ecology under these new conditions. The growth of one of the yeasts, Brettanomyces, is considered a contaminant and must be controlled. This issue of Winemaking Update explores a natural way to control Brettanomyces yeast and the volatile phenols they produce, with selected wine bacteria used to conduct malolactic fermentation.

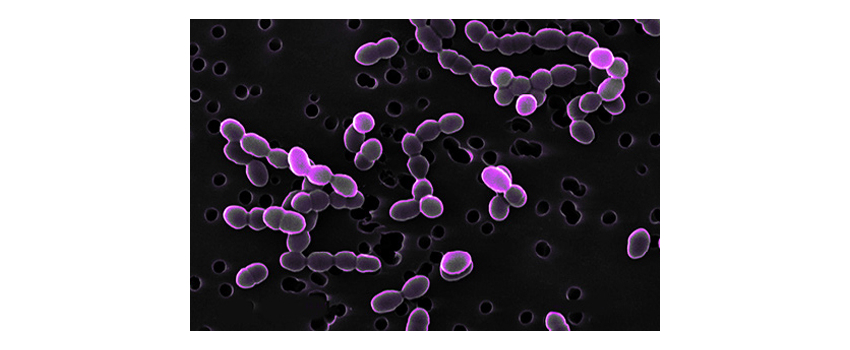

Brettanomyces - A recurrent culprit

Brettanomyces/Dekkera yeasts are well known wine spoilage micro-organisms that can damage wine quality, from increasing haziness to producing volatile phenols – aromatic compounds associated with medicinal, band-aid, barnyard, horsey and mousy offodours (Fugelsang et al. 1993, and Heresztyn 1986). Controlling the precursors of volatile phenols and the growth of this spoilage yeast in the winery is a major challenge, as it can develop even in difficult conditions, such as high alcohol, high pH, nutritional depletion, high sulphur dioxide (SO2), etc. Although Brettanomyces can be detected at any stage of the winemaking process, it is typically detected after alcoholic fermentation (AF) and before spontaneous malolactic fermentation (MLF) or during barrel aging (figure 1).

Ethylphenol metabolism

The off-odours are caused principally by 4-ethylguaiacol (4-EG) and 4-ethylphenol (4-EP). With Brettanomyces, these compounds are produced during the biotransformation of the hydroxycinnamic acids, p-coumaric acid and ferulic acid, which are precursors naturally present in grapes in the bound or free form. Only the free form is used by Brettanomyces. The transformation of these free precursors into 4-EG and 4-EP (figure 2) occurs in two steps : first with the cinnamate decarboxylase enzyme, followed by the vinylphenol reductase enzyme. Several factors influence the concentration of these precursors, ranging from the varietal, to viticultural conditions (hot climate, cold climate) and winemaking practices. According to a recent study by Schopp et al. (2013), Brettanomyces bruxellensis can metabolize only the free form of p-coumaric and ferulic acids. In fact, any conversion of coutaric acid (in the bound form) by the cinnamyl esterase enzyme, to p-coumaric acid (in the free form) by other wine micro-organisms (figure 2) can contribute to the increased production of ethyl phenols by B. bruxellensis (Osborne et al. 2013).

It is interesting to note that Brettanomyces is not the only micro-organism that can produce volatile phenols. Some lactic acid bacteria, such as Pediococcus and Lactobacillus (Couto et al. 2006) are also naturally able to produce volatile phenols from free hydroxycinnamic acid (p-coumaric and ferulic acids). Similar results were observed with some strains of Lactobacillus plantarum during research by Fras et al. (2014).

A recent study by Burn and Osborne (2013) showed that certain wine bacteria of the Oenococcus oeni species can metabolize coutaric acid into p-coumaric acid, through the action of one of their enzymes, cinnamyl esterase (figure 2), thereby increasing the levels of the volatile phenol precursors available for Brettanomyces.

Selected wine bacteria against Brettanomyces

The first step to controlling Brettanomyces is respecting winemaking best practices. It is important to have an integrated strategy that takes into account the interdependence of diverse wine parameters, such as grape quality, SO2, pH, wine temperature, nutrients, oxygen, barrel condition and oenological practices. Good cellar hygiene, reducing the lag phase between the end of AF and the beginning of MLF, and early stabilization, along with proper SO2 dosage, greatly minimize the risk of microbial spoilage. The winemaker’s strategy to limit the risk of developing Brettanomyces has three key factors: the presence of precursors for volatile phenols, the growth phases of Brettanomyces and the wine conditions. Selected wine bacteria can prevent Brettanomyces development by taking into consideration these three aspects.

Wine conditions

Secure, fast and complete alcoholic and malolactic fermentations, combined with early stabilization, help preserve the quality of the wine and limit the residual nutrients that Brettanomyces utilizes to survive and develop.

Preventing the presence of precursors for volatile phenol

Osborne et al. (2012) investigated the capacity of wine bacteria (O. oeni and L. plantarum, including selected bacteria) to degrade hydroxycinnamic acids bound to tartaric ester present in the wine into the free form, the precursors for volatile phenol production by Brettanomyces. The trials were done in Pinot Noir wine inoculated with selected wine bacteria, and the results compared to a control sample in which MLF was blocked. The researchers assessed the concentrations of hydroxycinnamic acids (esterified and free) after MLF. The variation in the concentrations of hydroxycinnamic acids indicates whether the wine bacteria can degrade certain acids, and make them available to the Brettanomyces for the production of volatile phenols.

They found that some strains of O. oeni wine bacteria clearly have the capacity to increase the level of coumaric acid (free form) in the wine and thus generate an increase in the level of ethylphenols in the presence of Brettanomyces.

This study sheds new light on the metabolic pathway of certain O. oeni strains which possess the cinnamyl esterase enzyme and can degrade coutaric acid into coumaric acid, for example.

Following these observations, we sought to characterize all our selected wine bacteria. The results show there is no change in the concentration of the hydroxycinnamic acids (both bound and free) in the wines inoculated with our bacteria compared to the control wine, where MLF was blocked.

Thus, our selected wine bacteria cannot degrade coutaric acid into coumaric acid, or any other bound hydroxycinnamic acid, which is the origin of the volatile phenol precursors responsible for the development of the off-odours associated with Brettanomyces. This led to the conclusion that the cinnamyl esterase enzyme, which is responsible for forming p-coumaric acid from coutaric acid, or any other free hydroxycinnamic acid is absent from our selected wine bacteria, which means they can be considered “phenol negative.”

The complete list of our selected wine bacteria characterized as phenol negative includes Lalvin VP41, PN4, Beta, Alpha, Lalvin 31, O-Mega, which are all in the species O. oeni, as well as our Lactobacilus plantarum V22. Therefore, the winemaker can choose one of these bacteria for MLF at no risk of producing precursors to volatile phenols.

Preventing Brettanomyces growth with secure and fast malolactic fermentation

The utilization of a selected yeast and proper yeast nutrition ensures the rapid onset, effective and complete AF, which, as we know, is part of an integrated strategy to prevent the development of Brettanomyces. Yet that does not guarantee results. The period from the end of AF to the start of MLF is particularly conducive to the development of Brettanomyces : the wine is not protected by SO2, there are still some nutrients available to the spoilage yeast, and competition from other wine micro-organisms is hardly a threat, as the yeast has finished and is dying off and the indigenous lactic bacteria are not yet established. The use of selected wine bacteria is a solution to shorten the time lapse between AF and MLF and thereby prevent the development of Brettanomyces.

Early inoculation with the wine bacteria, either right after AF or in co-inoculation (24 hours after inoculation with yeast), has proven to be a simple and effective method for preventing the development of Brettanomyces. In a study by Pillet et al. (2011), a Cabernet Franc from the Gironde region of France underwent co-inoculation trials with Inoflore that ensured rapid MLF. The analysis of the trial results led to an interesting discovery : the population of the non-Saccharomyces yeast (later revealed as Brettanomyces) was significantly lower in the samples of co-inoculated wine. During this trial, it was observed that the co-inoculation prevented Brettanomyces development and, consequently, volatile phenol production.

During a co-inoculation trial on a Cabernet Franc must (in the Languedoc-Roussillon region of France), compared to a spontaneous MLF wine, co-inoculation once again resulted in lower ethylphenol levels. The level of 4-ethylphenol is eight times higher in the control wine compared to the co-inoculated wine, and 4-ethylguaiacol is four times greater (see figure).

To prevent the development of Brettanomyces and the problems associated with this microorganism, the winemaker can use not only co-inoculation, but early or sequential inoculation with wine bacteria right after AF. In a study by Gerbaux et al. (2009) in a Burgundy Pinot Noir, it was shown in laboratory and cellar trials that early inoculation with wine bacteria, right after AF, was useful in controlling the proliferation of Brettanomyces. The pH and temperature can negatively impact the onset and progress of MLF, and increase the risk of producing volatile phenols. Launching MLF by inoculating with selected wine bacteria, instead of relying on the spontaneous onset of MLF, avoids exposing the wine unnecessarily to the risks of developing Brettanomyces, which are particularly high during the period preceding MLF. The results presented in table 2 show that MLF began much sooner in the wines inoculated with two different wine bacteria, which contributed to a shorter duration for the process and significantly reduced the concentrations of volatile phenols. The data from inoculation trials, done at two different cellar temperatures, were compared to the data from the control wine, which underwent spontaneous MLF. In all probability, the greater the risk of Brettanomyces growth, the earlier the wine should be inoculated with malolactic bacteria.

To summarize

Winemakers now have more information on the best way to prevent – and even treat – Brettanomyces contamination in wines. Inoculation with selected wine bacteria to induce and accelerate malolactic fermentation has been shown to be an effective means to prevent contamination. We know that inoculating the wine with a dose of >106 cells/mL of selected wine bacteria will stop the growth of this spoilage yeast. Managing the winemaking process through secure alcoholic fermentation and malolactic fermentation is a good starting point to prevent the development of undesirable indigenous flora. It is very important to carefully choose the selected bacteria based on its capacity to inhibit the production of free hydroxycinnamic acids, such as p-coumaric acid, precursor to volatile ethylphenols by Brettanomyces.

Lallemand wine bacteria, including Lalvin VP41, PN4, Beta, Alpha, Lalvin 31, O-Mega, which are all in the species O. oeni, as well as our Lactobacilus plantarum V22 do not have the cinnamyl esterase enzyme that leads to the transformation of this precursor in the free form, making it available to Brettanomyces. We call these Lallemand wine bacteria phenol negative. Moreover, appropriate inoculation strategies (co-inoculation, and early or sequential inoculation right after AF) have been shown to be effective tools to prevent the development of Brettanomyces. By choosing a phenol-negative wine bacteria and by carefully selecting the timing of inoculation with this bacteria, the winemaker can adopt an even more effective strategy to protect against the production of volatile phenols by Brettanomyces.

.For more information on this topic, contact our Lallemand Oenology experts here on Winemak-in or send us a direct message.

You can also go to our Website : www.lallemandwine.com or contact us :

Lallemand France/Switzerland/China

Lallemand SAS

fb.france@lallemand.com

Tel: +33.5.62.74.55.55

Lallemand Italia

fb.italia@lallemand.com

Tel: +39 (0) 45 51 25 55

Lallemand Península Ibérica

fb.espana@lallemand.com

Tel: (+34) 91 4415053

Lallemand Germany, Austria, Greece, Hungary, Israel, Cyprus, Malta, Poland

fb.eurocenter@lallemand.com

kburger@lallemand.com

Tel/Fax: (+43) 27 35 80 147

Ferment Croatia, Slovenia, Macedonia, Romania, Russia, Serbia, Moldavia, Ukraine

nmaslek@lallemand.com

Tel: (+385) 98 30 24 62

Lallemand North America, Mexico, Japan, Taiwan

gspecht@lallemand.com

Lallferm S.A. Chile, Argentina, Uruguay, Brazil, Ecuador, Colombia

pcarriles@lallemand.com

Tel: +54 (261) 425 67 89

Lallemand Australia , New Zealand

australiaoffice@lallemand.com

Tel: 61 (8) 276 1200

Lallemand South Africa

ploubser@lallemand.com

Tel: +27 21 913 7555